Today, Kangda Steel Balls will introduce tungsten steel balls to everyone, so that you can have a general understanding of them. I have noticed that the application areas of tungsten steel balls are becoming more and more extensive. However, many friends know very little about tungsten steel balls and are afraid to buy them without understanding their properties. After all, the price of tungsten steel balls is shockingly high. If you buy the wrong ones and spend unnecessary money, it can really hurt!

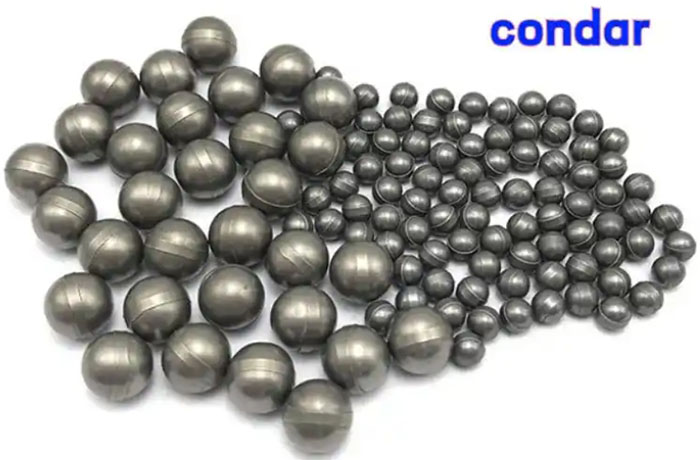

What is a tungsten steel ball? A tungsten steel ball, also known as a carbide ball or tungsten carbide ball, is a ball or roller made of cemented carbide. Its production process is complex and meticulous, involving multiple steps, with each step being strictly controlled to ensure the quality and performance of the final product.

The production and processing of tungsten steel balls are mainly divided into two stages: blank production and precision grinding. In the blank production stage, the first step is to mix, wet grind, dry, and screen the raw material powders of hard alloys (mainly including carbide powders of refractory metals such as tungsten carbide and titanium carbide, as well as metal powders of cobalt, nickel, molybdenum, etc. as binders). Subsequently, the molding agent is added and dried and sieved again to obtain a uniform mixture. Next, the tungsten steel ball blank is obtained by granulation, cold isostatic pressing, and sintering processes. The size and shape of the blank will be customized according to the requirements of subsequent applications.

In the precision grinding stage, the blank undergoes multiple rounds of grinding and polishing to achieve the required precision and surface smoothness. Advanced planetary grinding technology is widely used in this process, ensuring that the size and shape of each tungsten steel ball meet extremely high precision requirements through multiple steps such as dual rotation grinding and precision grinding. This high-precision machining process enables tungsten steel balls to exhibit their outstanding performance in high-end applications such as precision bearings, instruments, and meters.

The characteristics of tungsten steel balls are mainly reflected in their high hardness, wear resistance, corrosion resistance, and bending resistance. Its hardness usually reaches around HRA92, and some high-quality products can even reach a higher hardness value of HRA95 or above. This high hardness enables tungsten steel balls to maintain their shape and size stability even in harsh working environments, thereby extending their service life. At the same time, its wear resistance is tens to hundreds of times that of steel balls, which means that in applications that require high wear resistance, tungsten steel balls can significantly reduce replacement frequency and maintenance costs.

The application fields of tungsten steel balls are very extensive, covering almost all industries that require high hardness, high wear resistance, and high precision. In precision bearings, tungsten steel balls can provide stable rotational performance and longer service life; In instruments and meters, their high precision and stability ensure the accuracy of measurement results; Tungsten steel balls are also highly favored in industries such as pen making, spray painting machines, and water pumps due to their wear resistance and corrosion resistance. In addition, tungsten steel balls are widely used in fields such as oil fields, hydrochloric acid laboratories, hardness testers, fishing gear, counterweights, decoration, and precision machining.

The price of tungsten steel balls is influenced by various factors, including raw material costs, production and processing costs, market demand, and supply. Generally speaking, high-quality tungsten steel balls are relatively expensive due to their excellent performance and precise processing. However, with the continuous advancement of technology and the improvement of production efficiency, the production cost of tungsten steel balls is gradually decreasing, making their prices more affordable. Meanwhile, the intensification of market competition has made the price of tungsten steel balls more transparent and reasonable.

When purchasing tungsten steel balls, Kanda Steel Ball believes that in addition to focusing on price, attention should also be paid to product quality and performance. Some well-known tungsten steel ball manufacturers usually offer a variety of specifications and models of products to meet the needs of different customers. At the same time, they will also strictly control the quality of the products to ensure that each product meets the relevant standards and requirements. Therefore, when choosing tungsten steel balls, consumers should choose manufacturers with good reputation and guaranteed product quality to ensure that the purchased products can meet their needs.

In addition, for customers who need to customize tungsten steel balls, they can communicate with the manufacturer to customize suitable specifications and models according to their own needs. Manufacturers typically provide personalized solutions based on customers' specific requirements and ensure that the final product meets their expectations. This customized service not only improves the applicability of the product, but also provides customers with more choices and flexibility.

Overall, tungsten steel balls, as a high-performance alloy material, require multiple fine steps in the production and processing process to ensure their quality and performance. Its high hardness, wear resistance, corrosion resistance, and bending resistance make it widely used in multiple fields. Although the price of high-quality tungsten steel balls is relatively high, with the continuous advancement of technology and the improvement of production efficiency, their price is gradually decreasing and becoming more affordable. When purchasing tungsten steel balls, consumers should pay attention to the quality and performance of the product, and choose manufacturers with good reputation and guaranteed product quality. Meanwhile, for customers who require customized tungsten steel balls, they can communicate with the manufacturer and provide personalized solutions.

With the continuous advancement of technology and the expansion of application fields, the production technology and application areas of tungsten steel balls will also continue to develop. In the future, we can look forward to more efficient, environmentally friendly, and intelligent tungsten steel ball production technology and a wider range of application areas. At the same time, with the intensification of market competition and the continuous changes in consumer demand, tungsten steel ball manufacturers also need to constantly innovate and improve their products to meet market demands. This will inject new vitality and momentum into the development of the tungsten steel ball industry, driving its continuous progress.